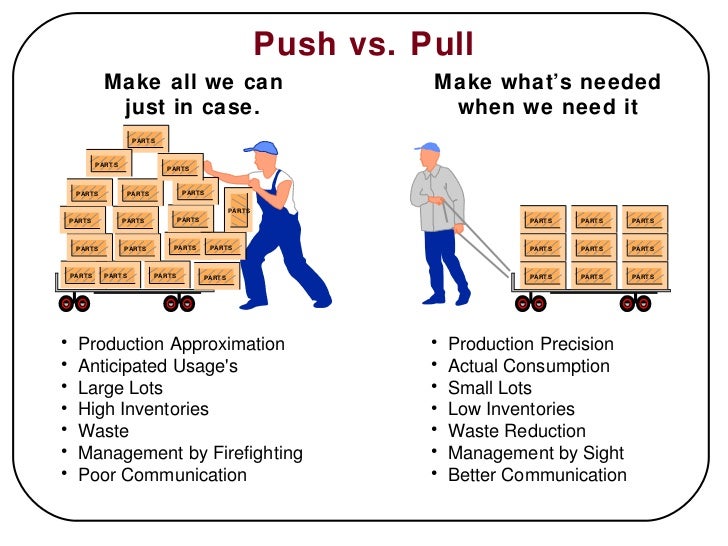

While inventory creates a safety net for companies, maintenance and potential waste of resources can have significant implications for companies and the environment. Manufacturers must evaluate and analyse each market and determine whether a JIT or JIC strategy is the best to follow.

JIT and JIC are two production strategies used by manufacturers that have both advantages and disadvantages to them. A manufacturing company will choose one of these strategies to follow for many reasons that include the products they are producing, the nature of the market and the nature of the economy.

Just in Time (JIT)

- A situation where a company does not allocate space to the storage of components or completed items,

- Instead orders or manufactures them when required.

- Large storage areas are not needed

- Items that are not ordered by customers are not made.

More information from this website.

Advantages

- Storage – no space required thus reducing costs

- Efficiency – Highly flexible, easy set-up for short runs (because of cell production)

- Stock control – none required also no left over stock one the product becomes obsolete.

- Waste – elimination of waste due to overproduction, left over stock, idle time, product defects and material processing.

- Traditions – Factory organised in cells/modules instead of departments based on function

Disadvantages

- Reliability – Part will need to be made, things could go wrong, delay in manufacture and transport to consumer

- Capital investment – high but machinery could be used for a variety of products

- Distribution – small delay as consumer waits for the manufacture and distribution.

Just in Case (JIC)

- A company produces a small stock of components or products and stores them as inventory.

- This is Just-InCase a rush order comes they have ready supply.

- Some products included may be products or components that take a long time to produce therefore reducing customer wait time.

Advantages

- Distribution – no delay as as parts are available.

- Reliability – Part is ready to be sent and probably has passed quality control.

- Market demand – manufacturer is able to keep up with a change in market demand

Disadvantages

- Efficiency – Not as effeiecwet as it is organised in departments often offsite.

- Capital investment – high but machinery could be used for a variety of products

- Storage – space required thus increasing costs

- Waste -some waste due to overproduction, left over stock, product defects and material processing.

- Traditions – Factory organised in departments based on function usually offsite bringing about added costs and transportation time

- Stock control – required also, may left over stock one the product becomes obsolete or market direction changes.

International Mindedness

Effective business processes and practices developed in some countries have been exported successfully.

Theory of Knowledge

Manufacturers decide whether to pursue JIT or JIC as a production strategy depending on their perception of where the market is going. To what extent do different areas of knowledge incorporate doubt as a part of their methods?

Something extra …

- Toyota You tube channel. Has some great videos