Consideration of the environmental impact of any product, service or system during its life cycle should be instigated at the earliest stage of design and continue through to disposal. Designers should have a firm understanding of their responsibility to reduce the ecological impact on the planet. Eco-design concepts currently have a great influence on many aspects of design.

The smart phone is an innovative example of converging technologies that combines multiple technologies into one space-saving device. The resultant reduction of materials, and energy used in production and distribution has environmental benefits.

Eco-design

Term: A design strategy that focusses on three broad environmental categories – materials, energy, and pollution/waste.

- This makes eco-design more complex and difficult to do.

The Major Considerations of the United Nations Environmental Programme Manual on Eco- design

The UN released a manual on Eco design in 1996. It outlined major considerations:

- reduce the creation and use of toxic materials

- increase recyclability

- reduce energy consumption

- increase use of renewable resources

- increase product durability – reducing planned obsolescence

- reduce material requirements for products and services

The emphasis of the guidelines will vary depending on the type of product to be designed and the target market.

Timescale for Implementing Eco-design

- Some factors that can influence the timescale include:

- cost, available technology,

- radical or whole system overhaul,

- eco-design is more complex

- all of which can add to the timescale.

The “cradle to grave” and “cradle to cradle” Philosophy

Term: Cradle to Grave – A design philosophy that considers the environmental effects of a product all of the way from manufacture to disposal.

- It is a key principle of the linear economy.

Term: Cradle to Cradle – A design philosophy that aims to eliminate waste from the production, use and disposal of a product. It centres on products which are made to be made again.

-

- It is a key principle of the circular economy.

- Made to be made – is when a product is designed it is conceived in such a way that it can be made again using the same/most materials/resources of the original product, once it has been disposed of.

- Cradle to Cradle ® (C2C) is a holistic approach to design popularized by Professor Michael Braungart and William McDonough. Braungart and McDonough offer Cradle to Cradle ®certification to products that measure up to the standards they set.

- According to their website (www.c2ccertified.org): “The target is to develop and design products that are truly suited to a biological or technical metabolism, thereby preventing the recycling of products which were never designed to be recycled in the first place.”

Life Cycle Analysis (LCA)

Term: The assessment of the effect a product has on the environment (LCA) through five stages of its life: pre-production; production; distribution (including packaging); utilization; and disposal.

- Designers use LCA to assess and balance environmental impact over a product’s life cycle.

- It can highlight areas with opportunities to reduce the environmental impact.

- It makes the designer to think about changing product design to reduce the impact such a green or sustainable product designs

LCA stages:

- pre-production;

- is the obtaining of natural resources;

- it can be very polluting (strip-mining) or can have a smaller effect on the environment (shaft mining),

- includes transporting the raw material to processing industries

- production

- is the processing of the resources and shaping etc. to make the product.

- Once again it could be damaging to the environment (such as a large factory spewing out smoke) or have a small impact (a carpenter hand crafting children’s toys)

- distribution including packaging;

- includes taking the product from the factory to the warehouse, from the warehouse to the store, and the package.

- It could have a large impact (as is the case with an imported object from around the world in a Styrofoam box) or a very low impact (made and sold in the same place with a biodegradable box or no packaging)

- utilization

- is about the product’s use and the effect that has on the environment.

- A diesel generator for example will pollute air and make noise pollution while a solar panel will make next to none.

- disposal

- depends on both the product and the method of disposal. Recycling one aluminum can will make less environmental problems than throwing one away even if they are identical.

- Biodegradable objects can be reused, recycled, or left to be broken down and add nutrients to the soil, depending on the object one or the other would be preferable.

- Paper is best recycled because of the chemicals used to make it and the logging of forests to obtain the pulp while a banana peel is completely useless for anything but compost.

Environmental considerations

- water and soil pollution

- water and soil degradation

- air contamination

- noise

- energy consumption

- consumption of natural resources

- pollution and effect on ecosystems.

Environmental Impact Assessment Matrix

The LCA matrix is a useful tool for designers of eco-products and systems.

- Benefits of organizing the life cycle stages and the environmental considerations into an environmental impact assessment matrix in which elements differ in importance according to the particular design context.

- It is targeted at particular product categories—products with high environmental impacts in the global marketplace, for example, washing machines and refrigerators.

- LCA identifies conflicts that have to be resolved through prioritization.

- It is not widely used in practice because

- it is difficult, costly and time-consuming.

- The complex nature of LCA means that it is not possible for a lone designer to undertake it and a team with different specialism is required.

- LCA is complex, time-consuming and expensive, so the majority of eco-designs are based on less detailed qualitative assessments of likely impacts of a product over its life cycle.

- However, in the re-innovation of the design of a product or its manufacture, specific aspects may be changed after considering the design objectives for green products, such as

- selecting less toxic materials or using more sustainable sources.

- a product may be distributed differently.

- its packaging may be redesigned.

- minimize the use of packaging.

- optimize energy efficiency in use.

- design for disassembly.

- minimize parts/components.

- use recyclable materials.

| ENVIRONMENTAL AREA: AIR POLLUTION | ||||||

|---|---|---|---|---|---|---|

| ACTIVITY | RISK IMPACT RATING (CIRCLE ONE NUMBER IN EACH ROW) | |||||

| Pre-production: Transport of all materials to factory | 5 | 4 | 3 | 2 | 1 | 0 |

| Production: Manufacturing process waste output | 5 | 4 | 3 | 2 | 1 | 0 |

| Distribution: Transport of product to retailers | 5 | 4 | 3 | 2 | 1 | 0 |

| Distribution: Manufacturing of packaging | 5 | 4 | 3 | 2 | 1 | 0 |

| Utilization: Use of product during working life | 5 | 4 | 3 | 2 | 1 | 0 |

| Disposal: Disassembly and recycling of materials | 5 | 4 | 3 | 2 | 1 | 0 |

Simple example of an environmental impact assessment matrix – from the IBO

- Environmental impact assessment matrices can be infinitely more complex, focusing on one particular stage of LCA at a time and breaking processes down into individual steps, often focusing on an output in terms of resources used, wasted and by-products generated and released.

- The simplest example is the use of a checklist to guide the design team during a product’s design development stages.

The roles and responsibilities of the designer, manufacturer and user at each stage of the product life cycle.

- Roles and responsibilities vary between them

- Clearly the user/consumer have little control in the early stages but more so in the products use and disposal.

- Similarly, with the designer and manufacturer.

| Pre-production | Production | Distribution | Utilization | Disposal | |

| Designer | Low | Mid-High | Mid-High | High | High |

| Manufacturer | High | High | Mid | Low | Low |

| User | Low | Low | Low | High | High |

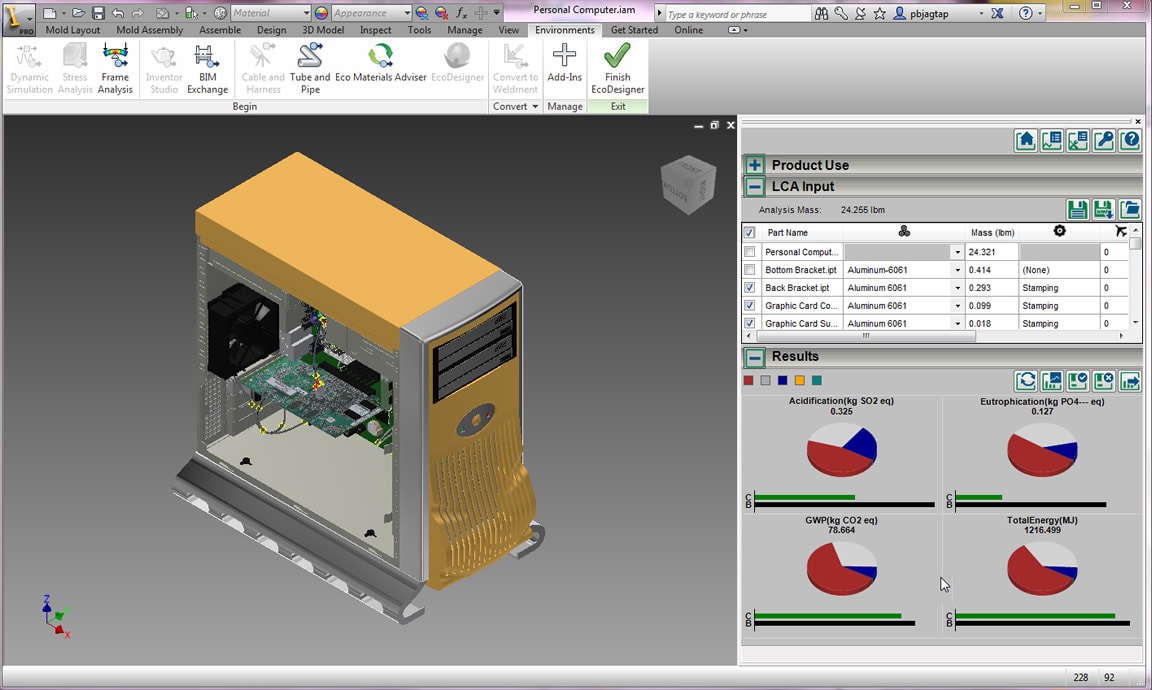

“Design for the Environment” (DfE) software

Term: Software that allows designers to perform Life cycle analysis (LCA) on a product and assess its environmental impact.

Design for the Environment description.

There is software available, such as Autodesk Inventor, Eco-designer or Solidworks that allows designers to DfE. They

- allow the designer to carry out LCA.

- select materials and manufacturing techniques that reduce environmental effects.

- run scenarios that can minimize materials.

- optimise designs to get cost effective products that are environmentally concerned.

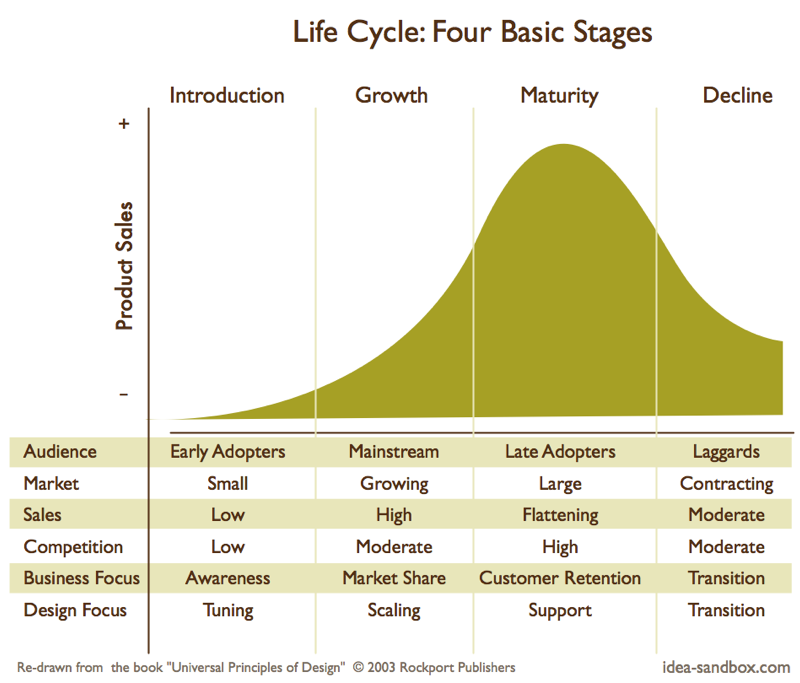

Product Cycle

Term: Product Cycle – Also known as the product life cycle, it is a cycle that every product goes through from introduction to withdrawal or discontinuation.

|

|

| Where is the computer mouse in he Product Life Cycle? – SMH Link to the article |

Four main stages

There are four main stages of the product life cycle which are, introduction, early, mature and late.

- During the early stages the product has just recently been introduced into the market and tends not to sell well and maybe overpriced in order to break-even. It also undergoes many changes.

- During the Mature stages of the product cycle the product is now reached its peak where little changes to its design occur and sells very well.

- During the late stage the product’s sales decline and becomes obsolete.

Designing is part of the product cycle.

- A need is generated and a product is designed, manufactured, and sold.

- Product eventually becoming obsolete (out of use).

- Distributors, retailers, accountants and production engineers, who all have an affect over the cycle, complicate the cycle.

- Unlike in the design process, the designer is not necessarily in control of the cycle.

- In CAD (computer aided design) and CAM (computer aided manufacture), the designer actually becomes part of the cycle by creating the prototype from a personal computer.

The role of the designer:

- Designing is part of the product cycle: as a need is generated, a product is designed, made and sold, eventually becoming obsolete.

- The cycle is complicated by distributors, retailers, accountants and production engineers, all of whom have an influence over the cycle. Although the designer is an integral part of the process, he or she is not necessarily in control (unlike in the design process).

- Computer-aided design (CAD) and computer aided manufacture (CAM), where a prototype is produced by the designer from his or her personal computer (PC), blurs this distinction.

The role of the manufacturer

- In the selection of manufacturing techniques – preferably limiting environmental affect – injection moulding produces very little waste

- Quality control – controlling errors and waste

- Specify standrad components and sub-assesmblies

- Attempt to minimise: energy usage, emissions, water pollution and other elements of the LCA.

- This can be done through the introduction of management systems.

The role of the user

- Market pull from consumers

- Spending patterns – a need for a durable product versus a disposable one

- Disposal of the product

- Consumers can force designers and manufacturers to be more green usually through their buying power

- Provide feedback to manufacturers

Converging Technologies

Term: The synergistic merging of nanotechnology, biotechnology, information and communication technologies and cognitive science.

| Advantages | Disadvantages |

|

|

- An example of converging technology is the smart phone.

- consider the smart phone as a converging technology in terms of the materials required to create it, its energy consumption, disassembly, recyclability and the portability of the devices it incorporates.

- Functionality: telephone. texting, apps, MP3 Player, video and still camera, phone book, etc

- Other examples include mobile health devices such as the FitBit or iWatch or other wearables that have integrated circuits that can monitor body functions.

- Wareable Article

- Digital Trends on wearables

International-mindedness

The differing stages of economic development of different countries/regions and their past and future contributions to global emissions is an issue.

Theory of knowledge

There is no waste in nature. Should areas of knowledge look at natural processes beyond human endeavour?

Something Extra …