Decisions on scale of production are influenced by the volume or quantities required, types of materials used to make the products and the type of product being manufactured. There are also considerations of staffing, resources and finance.

The growing phenomenon of mass customization brings consumers into the design process, allowing them to make choices that make a product unique, to make it their own. Companies have developed “design stations” in their retail stores where consumers can create virtual 3D models, “try them out” using digital technology and place their order.

Production Systems

- Craft production – A small-scale production process centred on manual skills.

- Mechanized production – A volume production process involving machines controlled by humans.

- Automated Production – A volume production process involving machines controlled by production computers

- See Productions systems for more details

One-off Production

- Is an individual product or a prototype for larger-scale production.

- Products maybe made often with craft production techniques or a combination of craft and machines.

- There is a close relationship between the manufacturer and consumer due to the user needs dominate.

- If a prototype is made then it is usually part of the realisation of a product and so the next step after testing and evaluating would be batch or continuos flow production.

- Examples of products made include prototypes (e.g. car or clothing production), specialist models, hand crafted items (e.g. jewellery, shaker furniture), specialist engineering, specialist architecture (e.g. individual homes, skyscrapers, hotels like the Hydropolis) and just plain old one offs (e.g. Ocean liners).

- With CAD/CAM (eg 3d Printing) one-off production can occur in the home.

Advantages

- Highly customisable to consumers needs.

- Flexibility for the designer and consumer.

- Allow for testing of prototypes before continuous flow production.

Disadvantages

- Can be expensive as any tools or machinery needed are included in the final cost.

- Time consuming if craft manufacturing techniques are used

- May be that the product is not designed for disassembly (DfD) there are no interchangeable parts.

Specialist Guitar Specialist Guitar |

Batch Production

- It is a limited production run (a set number of items to be produced).

- Batch production is a manufacturing method used to produce or process any product in batches, as opposed to a continuous production process, or an one-off production.

- Batch production is popular in bakeries and in the manufacture of sports shoes, pharmaceutical ingredients, inks, paints and adhesives.

- Can be mechanised or automated production

Advantages

- Cheaper than one-off production (economies of scale).

- Customisable products but not as highly as one-off production.

- Easily adjust to market demands or seasonal items

- Greater consumer choice (e.g. Swatch watches).

- For smaller or upstart companies that can’t afford continuous flow production.

- It can reduce initial capital outlay because a single production line can be used to produce several products.

Disadvantages

- Down time between productions runs when retooling.

- Products have to be stored raising the costs per item.

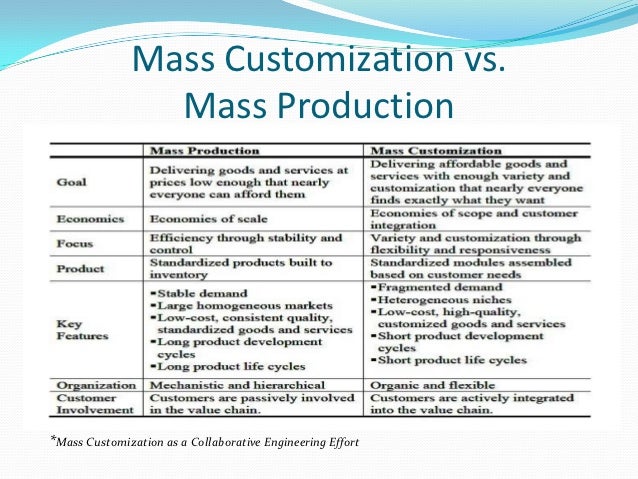

Mass Production

- The production of large amounts of standardized products on production lines, permitting very high rates of production per worker.

- Used when large quantities of products are needed such cars, bic pens etc

https://www.youtube.com/watch?v=3UjUWfwWAC4

Continuous Flow Production

- Continuous flow is a production method used to manufacture, produce or process materials without interruption.

- Is where thousands of standardised products are continuously made 24 hours a day 7 days a week.

- It is carried out to maximise production while reducing the costs of starting and stopping the production process.

- It can be mechanised or automated process with only a handful of workers needed.

Advantages

- Cheaper than other production methods (economies of scale).

- If a part or product needs replacing consumer is assured that it still exists (e.g. bic pens).

- Lack of inventory which reduces storage costs.

Disadvantages

- Standard products so less choice for the consumer.

- Automated production is high in initial costs

- Training of staff to run machines and CIM

Mass customization

- A CIM system that manufactures products to individual customer needs or wants.

- It benefits from economy of scale for a single products or thousands of them.

- The relationship between the manufacturer and customer becomes closer because the individual requirements of the consumer dominate.

|

- Customise you Nike shoe on Nikeid.

- Customised online and shipped directly from the factory

- A website dedicated to mass-customisation

Advantages

- Economies of scale are achieved even for small orders

- Highly customisable to consumer needs or likes

Disadvantages

- Long layover time from with product is customised to reaching the consumer.

- Very high initial capital costs

- Special training for employees

Design Stations

|

|

|

| A Sports Depot with a custom apparel station | Customising made easy at department stores |

- Macys Goes Millennial

- Custom Laser Bar at Macys

Selecting an appropriate scale of production

Manufacturers choose a scale of production for various reasons

-

- Product characteristics – complexity, features, design, product family, etc

- Staff skills – high tech skills for automation.

- Financial Considerations – is it cost effective to produce, profits, etc

- Material characteristics – plastics are suited to continuos flow production more than say certain metals or other materials.

- Size of market – Mont Blanc pens are geared to a market segment which is small whereas Bic pens target are wider market for cheap disposable pens.

- Nature of market – such as the variety of products expected by the consumer such as Swatch watches.

- Desired manufacturing processes – injection moulding is suited to continuos flow production because it an be fully automated and use cheap thermoplastics

- Desired production scale – such as one-off, batch or continuos.

Identify the production methods for certain products in the video.

NB: the above video refers to ‘Job Production’ which is the same as One-Off Production.

International Mindedness

Mass customization enables global products to become individual items.