Composites are an important material in an intensely competitive global market. New materials and technologies are being produced frequently for the design and rapid manufacture of high-quality composite products. Composites are replacing more traditional materials as they can be created with properties specifically designed for the intended application. Carbon fibre has played an important part in weight reduction for vehicles and aircraft. (2.2)

What is a composite?

A mixture composed of two or more materials with one acting as the matrix (glue) the other acts as a reinforcement (fibres/sheet/particles).

- It takes the form of fibres/sheets/particles (reinforcement) in a matrix (glue).

- The fibres/sheets/particles can be made from textiles, glass, plastics, wood and carbon.

- The matrix can be made from thermoplastics, thermosetting plastics, ceramics (e.g. concrete), metals.

- It is made via the process of weaving, moulding, pultrusion or lamination

Composition and structure of composites

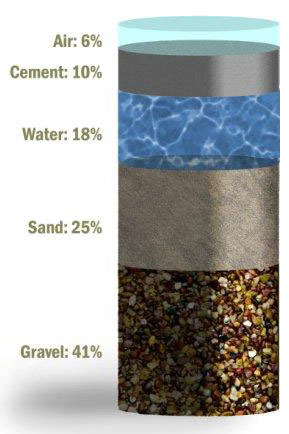

- Concrete – water, Portland cement, and aggregates (gravel etc)

- Engineered wood – also called composite wood, man-made wood, or manufactured board. gluing sheets (veneer), particles or stands of wood together.

- Plywood – sheets of venner glued together with the grain perpendicular to each sheet.

- Particleboard – chips of wood glued together (see above image).

- Fibreglass – stands of glass, formed into a matt and then covered in resin (polymer/thermoset plastic).

- Kevlar® – para-aramid synthetic fiber covered in a resin

- Carbon- reinforced plastic – carbon fibres formed into a matt (see above image) then covered in resin.

- Laminated veneer lumber (LVL) – uses multiple layers of thin wood assembled with adhesives

Advantages and disadvantages of composite materials

Design contexts of various composite materials.

- Concrete – skyscrapers, bridges, sidewalks, highways, houses and dams.

- Plywood – a wide range of uses from construction, internal (furniture, flooring, etc) and exterior uses (such as marine ply for boats).

- Particle board – used in furniture (such wardrobes, wall units, TV cabinets), shelving, toys, and wall linings

- Fibreglass – boats, pools, pipes, bathtubs, motor industry (vehicle bodies)

- Kevlar – armour, high performance canoes or sports equipment, ropes, military applications, tyres, sails,

- Carbon re-inforced plastic – high performance car racing, sports equipment (golf clubs, etc), aviation (the Boeing Dreamliner)

- Laminated veneer lumber (LVL) – structural applications such as in buildings.

International-Mindedness

Many composite materials are expensive to produce and their dissemination globally is limited.