The rapid pace of scientific discovery and new technologies has had a major impact on material science, giving designers many more materials from which to choose for their products. These new materials have given scope for “smart” new products or enhanced classic designs. Choosing the right material is a complex and difficult task with physical, aesthetic, mechanical and appropriate properties to consider. Environmental, moral and ethical issues surrounding choice of materials for use in any product, service or system also need to be considered.

Materials are often developed by materials engineers to have specific properties. The development of new materials allows designers to create new products, which solve old problems in new ways. For example, the explosion of plastic materials following the second world war enabled products to be made without using valuable metals.

Physical Properties

Term: Relates to the amount of matter that is contained with a specific material. It is often confused with weight understandably as we use Kg to measure it. Mass is a constant whereas weight may vary depending upon where it is being measured.

Term: Relies on mass and gravitational forces to provide measurable value. Weight is technically measure as a force, which is the Newton, i.e. a mass of 1 Kg is equivalent to 9.8 Newton [on earth].

- Read the section on Mass from Wikipedia

Term: The quantity of three-dimensional space enclosed by a boundary, for example, the space that a substance solid, liquid, gas, or shape occupies or contains.

Term: The mass per unit volume of a material. Its importance is in portability in terms of a product’s weight and size. Design contexts include, pre-packaged food (instant noodles) is sold by weight and volume, packaging foams.

- Design contexts include:

- any other context where weight and volume are important.

- pre-packaged food (instant noodles) is sold by weight and volume is important.

- packaging foams/material volume is important.

Term: The measure of a material’s ability to conduct electricity. A material with low resistivity will conduct electricity well.

- It is important when selecting materials as conductors or insulators

- Design contexts include: electrical plugs.

Electrical Insulator

Term: Reduces transmission of electric charge.

Thermal Conductivity

Term: A measure of how fast heat is conducted through a slab of material with a given temperature difference across the slab.

- It is important for objects that will be heated or must conduct or be insulated against heat gain or loss.

- Design contexts include: pots & pans.

Thermal Expansion (expansivity)

Term: A measure of the degree of increase in dimensions when an object is heated. This can be measured by an increase in length, area or volume. The expansivity can be measured as the fractional increase in dimension per kelvin increase in temperature.

- It is important when two dissimilar materials are joined. These may then experience large temperature changes while staying joined.

- Different materials (even within the same material group eg metals) expand at different rates.

- Design contexts include: oven doors, glass pot lids with metal rims.

Hardness

Term: The resistance a material offers to penetration or scratching.

- Design contexts include: ceramic floor tiles that extremely hard and resistant to scratching.

Mechanical Properties

Tensile Strength

Term: The ability of a material to withstand pulling (apart) forces.

- It is important in selecting materials to resist stretching.

- Design contexts include: ropes (climbing or towing), cables (in elevators) and fishing lines.

https://www.youtube.com/watch?v=CeOklEyUw0I

Compressive Strength

Term: The ability of a material to withstand being pushed or squashed.

- Design contexts include: ceramic floor tiles, concrete and bricks for buildings or anything that requires to bear weight.

Stiffness

Term: The resistance of an elastic body to deflection by an applied force.

- It is important for maintaining shape is an important performance.

- Design contexts include; aircraft wing, diving boards or panels on cars.

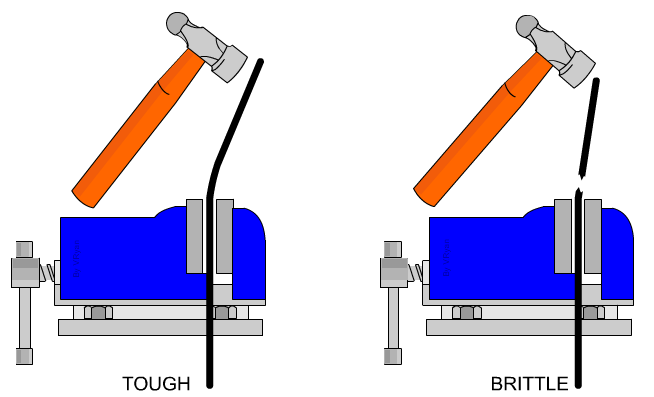

Toughness

Term: The ability of a material to resist the propagation of cracks.

- It is important where abrasion and cutting may take place.

- Design contexts include:

- any design context where impact is likely.

- automobile bumpers

Brittle (Brittleness)

Term: Breaks into numerous sharp shards.

- Typically has low toughness.

- Design contexts include: glasses

Ductility

Term: The ability of a material to be drawn or extruded into a wire or other extended shape.

-

- It is important when metals are extruded (extrusion).

- Typically has high toughness.

- Design contexts include production of extended extrusions.

- (not to be confused with malleability: the ability to be shaped plastically – see in below section).

Stress/Strain

Stress

Term: The load on a structural member divided by its cross-sectional area is called the “stress in the member”.

Strain

Term: The response of a material due to stress, defined as the change in length divided by the original length.

Young’s Modulus

Term: A measure of the stiffness of an elastic material and defined by stress/strain.

Stress/Strain Graph (Curve)

- The elastic region is generally a straight line.

- At the limit of proportionality it changes to a curved line which becomes the plastic region.

- Every material will perform differently under the application of stress and therefore each material’s graph will be different.

- We can identify and collect considerable amounts of information from a Stress-Strain graph.

- It is important when selecting materials.

- Important to intensify features of the stress/strain curve.

- Important to identify Stress/strain curve of various material groups.

Features of a Stress/Strain Curve Features of a Stress/Strain Curve |

Stress/Strain Graphs for Ductility/Stiffness Stress/Strain Graphs for Ductility/Stiffness |

Elasticity (Elastic region)

Term: The extent to which a material will return to its original shape after being deformed.

- A material behaves elastically, when the stress on the material is released before it breaks, the extension (strain) relaxes and the material returns to its original length or shape.

- If you squash a drinking

- Elastic video clip

Plasticity (Plastic region)

Term: The ability of a material to be changed in shape permanently.

- When bent/deformed beyond yield point and the stress is removed, it cannot change back to original shape.

- It maintains the new shape or stretches/tears/breaks.

- Plastic Video Clip

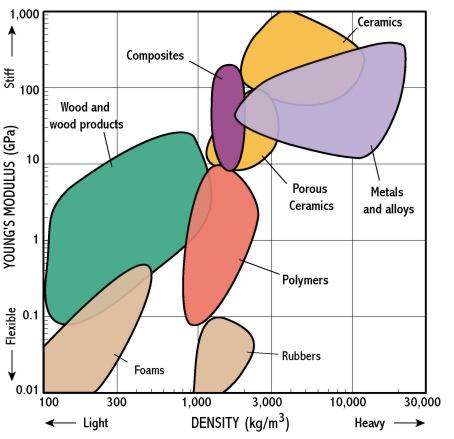

Material Selection Charts

Term: A chart used to identify appropriate materials based on the desired properties.

- You can drill down to specific materials in these charts.

- More selection charts from Cambridge University

NB: Using stress/strain graphs and material selection charts to identify appropriate materials. Students are expected to be able to interpret stress/strain graphs and material selection charts to identify appropriate materials depending on the context.

Aesthetic Characteristics

Term: Aspects of a product that relate to taste, texture, smell and appearance.

Term: Aesthetic Appeal – Favourable in terms of appearance.

- What determines aesthetic appeal is when a product is attractive to look at or pleasing to experience. It is through our senses.

- Some aesthetic characteristics are only relevant to food, while others can be applied to more than one material group.

- Although these properties activate people’s senses, responses to them vary from one individual to another, and they are difficult to quantify scientifically, unlike the other properties.

-

- Smell: the ability to perceive odours such as sweet, acrid or fragrant

-

- Taste: sour, sweet, spicy.

-

- Sound: related to pitches but also the sound of a crisp apple or a chip/crisp bag that makes a crinkling sound.

-

- Texture: it is how something feels or looks, it can be rough or smooth

-

- Appearance: the design of appearance in a product must be aesthetically pleasing to attract a customer. unless it is for a certain market.

- Colour: can be warm (e.g. browns) or cool (eg blues) can have psychological affects (e.g. greens are calming)

- Shape: geometric or organic.

- Appearance: the design of appearance in a product must be aesthetically pleasing to attract a customer. unless it is for a certain market.

Properties of Smart Materials

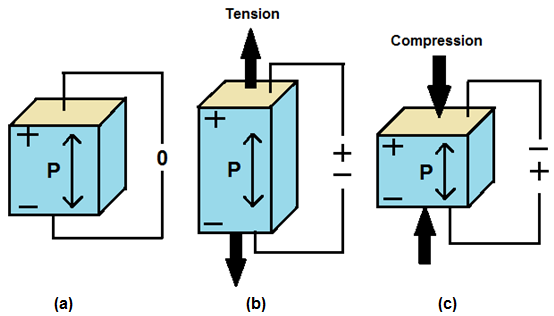

Piezoelectricity

- Piezoelectric materials give off a small electrical discharge when deformed.

- When an electric current is passed through it, it increases in size (up to a 4% change in volume).

- These materials are widely used as sensors in different environments.

- Piezoelectric materials can be used to measure the force of an impact, for example, in the airbag sensor on a car. The material senses the force of an impact on the car and sends an electric charge to activate the airbag.

|

|

Shape memory

- Shape memory alloys (SMA) are metals that exhibit pseudo-elasticity and shape memory effect due to rearrangement of the molecules in the material.

- Pseudo-elasticity occurs without a change in temperature. The load on the SMA causes molecular rearrangement, which reverses when the load is decreased and the material springs back to its original shape. The shape memory effect allows severe deformation of a material, which can then be returned to its original shape by heating it.

- Design contexts include frames of glasses, medical tools and antennas for mobile phones.

- Robotic limbs (hands, arms and legs) use shape memory properties.. It is difficult to replicate even simple movements of the human body, for example, the gripping force required to handle different objects (eggs, pens, tools).

- SMAs are strong and compact and can be used to create smooth, lifelike movements. Computer control of timing and size of an electric current running through the SMA can control the movement of an artificial joint.

- Other design challenges for artificial joints include development of computer software to control artificial muscle systems, being able to create large enough movements and replicating the speed and accuracy of human reflexes.

Photochromicity

- Photochromicity refers to a material that can described as having a reversible change of colour when exposed to light.

- A chemical either on the surface of the lens or embedded within the glass reacts to ultraviolet light, which causes it to change form and therefore its light absorption spectra.

- Design contexts include: One of the most popular applications is for colour-changing sunglass lenses, which can darken as the sun brightens.

Magneto-rheostatic & Electro-rheostatic

- Electro-rheostatic (ER) and magneto-rheostatic (MR) materials are fluids that can undergo dramatic changes in their viscosity.

- They can change from a thick fluid to a solid in a fraction of a second when exposed to a magnetic (for MR materials) or electric (for ER materials) field, and the effect is reversed when the field is removed.

- Design contexts include :

- MR fluids for use in car shock absorbers, damping washing machine vibration, prosthetic limbs, exercise equipment and surface polishing of machine parts.

- ER fluids have mainly been developed for use in clutches and valves, as well as engine mounts designed to reduce noise and vibration in vehicles.

Thermoelectricity

- Thermoelectricity is, at its simplest, electricity produced directly from heat. It involves the joining of two dissimilar conductors that, when heated, produce a direct current.

- Design contexts include: Thermoelectric circuits have been used in remote areas and space probes to power radio transmitters and receivers.

International mindedness

Smart materials are likely to be developed in specific regions/countries and their benefits can be limited globally in the short term.

Something Extra …

- Watch the other smart material videos from the above PBS series.

- Overview of Properties