Typically hard and shiny with good electrical and thermal conductivity, metals are a very useful resource or the manufacturing industry. Most pure metals are either too soft, brittle or chemically reactive for practical use and so understanding how to manipulate these materials is vital to the success of any application.

Extracting metal from ore

-

Extraction takes place locally with added value often occurring in another country. (Int Mind). Australia has an abundance of Iron ore which is mined and then shipped to China and Japan where is it made into steel. Iron ore is 81 USD per tonne and Steel 672 per tonne in October 2014.

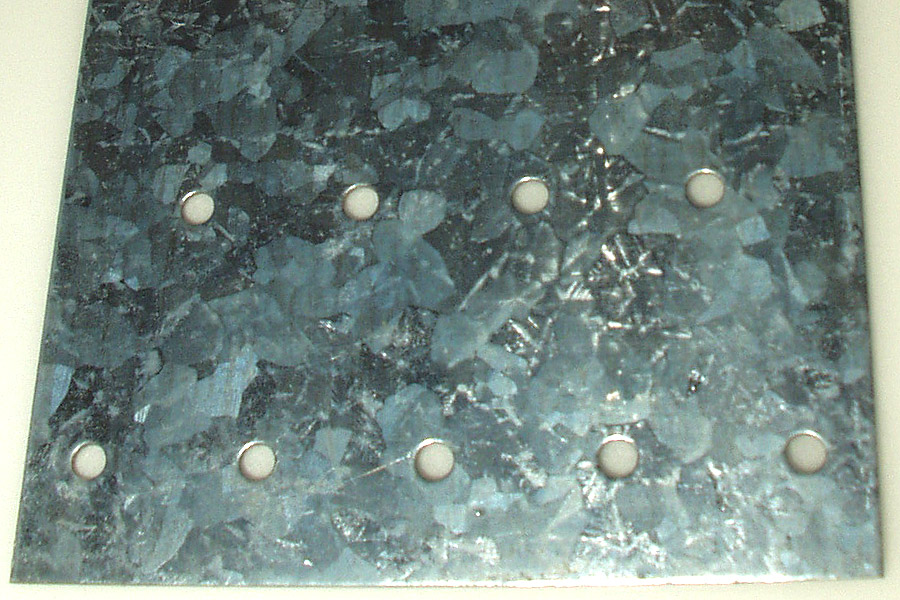

Grain size (Metals)

Metals are crystalline structures comprised of individual grains.

- The grain size can vary and be determined by the heat treatment.

- Reheating a solid metal or alloy allows the grains to change their structure.

- Slow cooling forms larger grains

- Rapid cooling (quench) forms smaller grains.

- Directional properties can be formed by selectively cooling one area of the solid.

- Grain size in metals can affect the properties:

- tensile strength – coarse grains the stronger a metal

- toughness – large or coarse grains the tougher the metal

- ductility – coarse grains the more ductile a metal

- brittleness – the smaller the grains the more brittle the metal

- flexibility/malleability – coarse grains the more malleable a metal

- can affect density

Modifying physical properties

Alloying

Alloys are a mixture that contains at least one metal.

- It can be two or more metals such as Bronze: Cu + Sn

- It can be a metal and non metal such as Carbon Steels: FE + C

Alloys compared to pure metals

- Alloying increases strength and hardness

- Alloying reduces malleability and ductility, of alloys compared to pure metals.

- This is due to the presence of “foreign” atoms which interfere with the movements of atoms in the crystals during plastic deformation

Work hardening (Cold working or Strain Hardening)

Is the process of toughening the a metal through plastic deformation.

Metals work-harden after being plastically deformed, much like when you twist a soft drink can back and forward and then it get gets stiff and then eventually fails (breaks).

Tempering

Tempering is a heat treatment process

- Usually carried out after hardening of a metal to:

- increase its toughness and ductility

- decrease hardness and brittleness

- Remember a hard material will have low toughness and vice versa.

Design criteria for super alloys

Superalloys: is an alloy that exhibits excellent mechanical strength, resistance to thermal creep deformation, good surface stability and resistance to corrosion.

Superalloys can be used at high temperatures, very close to their melting point. The strength of most metals decreases as the temperature increases.

Super alloys are used in Aerospace (e.g. rockets), Aviation (e.g. turbines), Chemical processing industry, nuclear reactors and much more.

Two criteria for super alloys are creep and oxidation resistance.

Creep

- Creep is the tendency of a metal (or material) to slowly move or deform permanently due to the long term exposure of stress that are below the yield strength or ultimate strength of the metal. Creep is more severe when metals are subjected to near the melting point heat for long periods of time. (Wikipeadia 2007)

Oxidation resistance

- Oxidation is the interaction between oxygen and different substances when they make contact, such as rust Fe2O3

- Oxidation resistance is the ability of a material to resist the direct and indirect attack of oxygen (oxidation) and degradation.

Recovery and disposal

Of metals and metallic alloys

- Metals and metallic alloys are so widely used.

- They are easily recyclable

- They can be indefinitely recycled

- It can reduce the emissions and the affect on the environment

- Reduce energy required to produce new metals

- fro example up to 95% energy savings in using recycled Aluminium.

Design Contexts

Ferrous Alloys contain iron (makes them magnetic). Non-ferrous contains no iron.

Where different metals and metallic alloys are used

Ferrous Alloys

- Mild Steel – Carbon content of 0.1 to 0.3% and Iron content of 99.7 – 99.9%. Used for engineering purposes and in general, none specialised metal products.

- Stainless Steel – Made up of Iron, nickel and chromium. Resists staining and corrosion and is therefore used for the likes of cutlery and surgical instrumentation.

- Cast Iron – carbon 2 – 6% and Iron at 94 to 98%. Very strong but brittle. Used to manufacture items such as engine blocks and manhole covers.

Non-ferrous Alloys

- Aluminium – An alloy of aluminium, copper and manganese. Very lightweight and easily worked. Used in aircraft manufacture, window frames and some kitchen ware. Pure Aluminium can be used in drink cans.

- Copper – Copper is a natural occurring substance. The fact that it conducts heat and electricity means that it is used for wiring, tubing and pipe work.

- Brass – A combination of copper and zinc, usually in the proportions of 65% to 35% respectively. Is used for ornamental purposes and within electrical fittings.

- Silver – Mainly a natural substance, but mixing with copper creates sterling silver. Used for decorative impact in jewellery and ornaments, and also to solder different metals together.

- Lead – Lead is a naturally occurring substance. It is heavy and very soft and is often used in roofing, in batteries and to make pipes. (from CastleMetalsEurope)

International Mindedness

Extraction takes place locally with added value often occurring in another country.